Everyone knows the cartridge system of microcomputers from the 80s. The MSX, a machine from that era, is no exception to the rule.

When you don't know anything about this type of machine, and when you finally get one, the first thing that comes to your mind is to see how it works. And so to do this, insert a cartridge, if possible of games, obviously!

This is when the problems start. How to do today when MSX has been commercially dead for more than 30 years. How to find such cartridges. It is of course possible to find them on the second-hand market. But buying 10 cartridges to test 10 games, well, that's not really viable.

The idea came very quickly to see if it was not possible to have a cartridge that could be refilled on demand, by SD card or USB device.

The Carnivore 2 cartridge, which also offers extras, uses a FLASH card to operate. You have to be able to find a compatible flash card, which is not always easy. I was never able to use the one I bought. The FPGA was poorly soldered and the cartridge quickly became unstable.

Straight into the trash :-(

There is the MegaFlashROM_SCC+_SD. It's the only one I managed to use. But to use it, there is a whole procedure to follow which is boring. And if you don't do this every day, you will have to find the documentation each time to successfully re-initialize the cartridge and copy your new game into it. The least we can say is that this solution is not practical at all. In addition, you have to use utilities that are provided in the cartridge while understanding what you are doing. And when you don't know anything about MSX, it's not engaging!

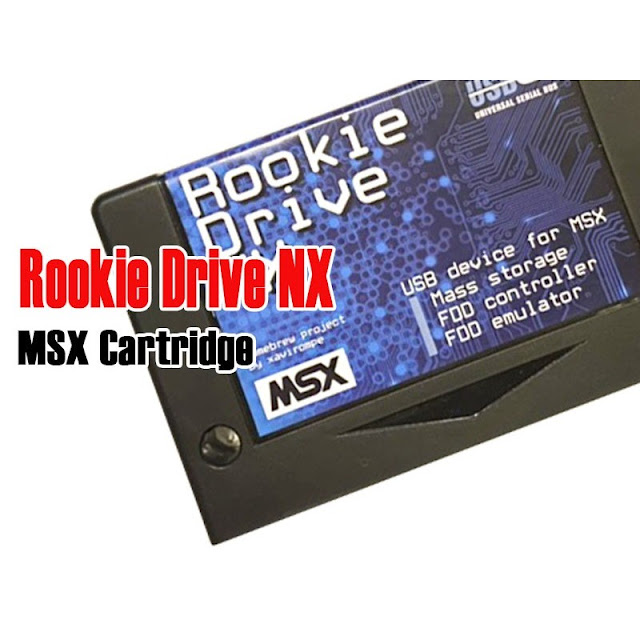

There is also the solution using a USB device like a key. For this, the rookie-drive-nx cartridge seems ideal. But also, after reading the documentation, I have never been able to get a USB device to be accepted by this cartridge: frustrating.

There is also the SD 512 but given the price of my three previous purchases, I decided I was going to discontinue the charges. So I haven't tested it.

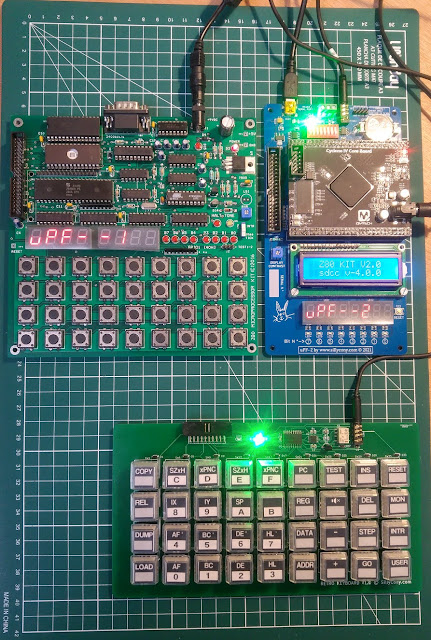

Because, in fact, my goal was to test as easily as possible an MSX board that I had just built, Sergey Kiselev's OMEGA computer.

So... I was looking for a solution to make this machine execute something in a simple way. This is how the idea of creating a cartridge that can be downloaded via USB came to me.

I don't know if this is the easiest solution at the moment because I'm in the design phase and it's not yet finished despite several previous prototypes.

But I know that once finished, the cartridge will be very easy to use. Simply insert it into the cartridge port of the MSX machine while also connecting it to the USB port of your PC. Dragging and dropping your binary file onto the cartridge, which will be seen as a USB key, will be enough to make the ROM for the MSX available in a few seconds.

If the final solution for my cartridge is not ready yet, I am posting about it now because I have almost achieved what I wanted.

But why is the current beta version not satisfactory?

Well it's very simple: because the USB protocol imposes regular requests from the host to the device to check its proper functioning. And it happens every few seconds.

And? Well, the response process requires the processor on the cartridge to respond ;-). And that takes time. Even if the processor used is fast, while it responds to the USB request, it cannot respond to computer access via the cartridge bus. Result: the MSX computer crashes! But, when the USB cable is unplugged, everything works as expected, as shown in the picture above.

I even planned the automatic RESET of the MSX computer while loading a new binary, so that it then restarts on its own on the new game, or new application. It works very well.

I therefore need to dissociate the USB bus management function from that of the MSX bus management. Because I don't use a FLASH strictly speaking, but the flash contained inside the processor. 'Small capacity' flashes in DIP housing and parallel addressing are becoming more and more difficult to find and more and more expensive.

So I don't have this problem with a processor equipped with the desired amount of Flash. In addition, it makes routing the printed circuit easier.

The final cartridge diagram looks like this:

I know, it's difficult to read. It's just a screenshot. But we can notice two big circuits there. These are the two processors used. The one on the right is in charge of the USB port, the one on the left is in charge of storing the binary of the cartridge and presenting it to the MSX bus.

This will cost a little more to produce than expected, but as the two processors are the same models, I will be able to take advantage of the quantity order to reduce the final price.

The software is ready and validated. All I have to do is implement each processor with its part and add a small communication protocol between them. The most 'tricky' part consists of creating a new printed circuit board with more components. But I think I can use the design of the current cartridge to facilitate this new implementation.

I must say that this is now the second project that I have carried out with a professional type process with all that this implies of prototyping, extensive testing taking into consideration a whole bunch of parameters including price, ease of realization, reliability etc etc...

I must say that it is a very enriching experience... When I think of what the type of job I had at the French university was, just a few months ago... What mediocrity!