This time, it is the machine of a French musical group which made itself known in the early 80s. History does not say whether or not this machine was part of the first successes of this group. Good question, by the way...

I have to admit that of all the Drumulators I have worked on, this one is in the best cosmetic condition. Almost perfect.

Let's go for the identity of the machine:

With the owner's tour of the exterior done, the big question: what about the interior? Because I was given to seeing dramatic things, of the true-false geek type who tried to add sound ROMs but who above all succeeded in crashing the machine by adding an incredible number of wires and modifications to the motherboard etc, which took me hours to remove!

In addition I have doubts about this Drumulator: result of tests or naval battle?

But no, there too, a nice surprise inside. No catastrophe in sight, at least other than a breakdown due to the machine itself and not as a result of outrageous tinkering.

We see very clearly that the machine has been updated with version 3 of the firmware for MIDI management. A MIDI input adapter card has been added as required, and placed/glued correctly.

It is even possible to say that the original ROM was removed with a screwdriver since we can clearly see the surface condition of the first resistor above the ROM whose coating was burst with the place which served as a support for the screwdriver.

The battery has never been changed. Luckily, it didn't sink. I checked her, she's dead. As a result, sequence saving should no longer have been working for a long time. I imagine it is mainly used in MIDI.

You will have to remove it anyway and place a standard 20CR32 support somewhere on the case.

Little check, at least the voltage selector is correctly positioned on 230V:

Small observation, the motherboard also has an identification number. It is not the same as that of the machine :

The usual checks having been carried out, what is the problem with this machine? At first glance, it seems simple since the machine does not turn on at all.

Power problem or CPU boot problem? Again the first observations are simple, the motherboard does not have any DC voltage. Neither on the analog part, nor on the digital part.

We go back to the source: no sign of alternating voltage either at the two secondaries of the transformer. Hmm... We're getting closer!

The mains voltage nevertheless arrives at the primary of the transformer. No sign of heat or burnt, it does not seem that the machine was connected to 110V.

All that remains is to test the primary windings which are, at 230V, connected in series. The observation is clear, one of the two primaries is cut. The transformer is therefore inoperative.

This is very strange. Transformer connections appear good. No burnt rifle, no burnt marks, no hot smell. What could have been the cause of this breakdown? A manufacturing defect in the transformer?

Now knowing this machine quite well, to further investigate I will connect the digital part of this Drumulator directly to the 5V of a protected laboratory power supply. Even if the processor does not start, this will allow me to check the approximately real 'digital' consumption of the board.

A few days later:

After connecting a direct current power supply directly to the two terminals of the diode bridge of the 5V part: 1.2A at 6V at the output of the power supply, although programmed for 10V, and 0V at the output of the large 5V regulator placed on the metal part of the case:

Simple conclusion: regulator dead. I forgot to specify, but according to tests carried out on different Drumulators, in normal operation, that is to say with the displays on, the average consumption of the digital part of a Drumulator is around 1.2A. So, with the regulator in the regulation loop, I already have the 1.2A consumed and 0V in power on the logic circuits.

But at this stage, I still have to confirm that it is indeed the 5V regulator that is dead. So this time I connected the DC power supply set this time to 5V, directly in place of the Drumulator regulator output. To do this, I cut the three wires connecting the 5V regulator to the motherboard.

And this time, I have consumed 1.2A but with the logic circuits supplied at 5V. Confirmation therefore that the 5V regulator of the Drumulator is indeed dead. But, obviously, the machine does not start.

The design problem of this machine remains for me the detection of power supply operation. EMU has implemented a complex system to ensure that the machine's three power supplies are present in order to authorize the microprocessor to exit RESET. This doesn't do much except make testing the operation of the machine much more difficult. For example, it is impossible to test the digital part if the analog part is not powered. The best thing to do is to remove the power supply monitoring circuit and directly shunt the validation outputs to the desired potential.

All the transistors in this section are used to test the validity of the machine's three power supplies, and also to generate the processor RESET signal. RESET signal that this system generates poorly, which deteriorates over time, and which ends up no longer working at all. This is obviously also the case on this machine.

And I'm not talking about the different power supplies generated in all directions, which must be provided as best as possible during the test phase in order to put the digital part in 'potential' starting condition.

Brief! Having spent some time making the necessary modifications just to get this machine into potential boot condition, I ended up getting my favorite message on the displays:

At this point, I can only confirm that the 'computer' part of the machine is working. I don't know anything yet about the waveform sequencer part, nor about the analog output.

The only thing I can do right away is to change the faulty digit:

I seem to have one or two displays of this type in stock.

I will now pause troubleshooting this machine. To continue in better conditions, I need to redo the power supply, starting by finding a compatible transformer, i.e. with two output voltages available, as well as replacing the original 5V regulator with a switching model, more reliable and dissipating much less heat :

I have made this type of modification on several machines with very good operating results.

Updated 06/05/2024

I finally received the transformer necessary to put the machine back into service.

It is not very easy to find a transformer with the necessary number of windings for this type of application. During my previous modification of this type, I found a transformer with a lower voltage for manufacturing the +5V. Luckily I use a switching regulator now to generate this voltage needed for all the digital part of the electronics.

And, consequently, I removed the linear regulator fixed on the metal frame of the Drumulator, acting as a thermal radiator for the evacuation of the heat emitted wastedly by this original regulator.

I removed also the original transformer which had one of the defective secondary windings.

And, before placing the new transformer, look for the direction of the windings. Indeed, for the analog part, I must put the two windings in series, the midpoint therefore making it possible to create the reference of a symmetrical power supply, while for the digital part, I must put the two windings in parallel in order to benefit from of greater power with the base voltage of a winding.

The problem with this transformer is that the magnetic direction is absolutely not indicated. Each winding has wires of the same color. It is therefore necessary to carry out the tests 'brutally' while still protecting yourself from magnetic short circuits. The use of a very low power bulb allows it to act as an 'automatic' fuse.

It is also important to wire the primary of the transformer in the correct way. Everything goes through a single connector on the Drumulator. This was not the best way to do it in my opinion. Besides, this would no longer be authorized today. It is therefore necessary to find the way in which the primary windings are connected according to the voltage selector.

|

| Art? |

Unfortunately, it will not be possible to wire the windings of the new transformer in the same way. In fact, it does not have two separate primary windings but only one primary winding with a central tap for 110V. You will need to configure the wiring for a 230V connection. This will not pose a problem given that the machine is and will most certainly remain in France.

Obviously, the large power connector doesn't like to be handled too much. Some of the wire strands were pinched too hard when crimping them into the terminals. With corrosion attacking the materials, it becomes brittle and, inevitably, ends up breaking at the connector pin. The only way to remove the pin to re-solder the wire is to push on it using a medium-hot soldering iron so that the plastic melts enough to allow its extraction.

This allows you to do a much cleaner job than trying to solder the wire with the lug in place. I have seen interventions of this type that are really not clean.

In the end, it's done well, but it takes a lot of time...

Once this connector was repaired, I was able to start installing the new transformer. Fixing it does not pose any particular problem, except that you will still have to cut the stem of the screws, which are too long.

Rewiring the transformer does not pose any particular problem either, except for the attention and the test before powering up, because in the event of a big problem, it would be possible to damage the electronics of the machine . This is the critical and risky point of the entire operation of putting this Drumulator back into service.

After an hour of rewiring, I will be able to plug the new transformer onto the Drumulator motherboard. This will not pose a problem for the generation of +5V given that I have not yet equipped the machine with the necessary switching regulator, on the other hand it is quite different for the symmetrical analog power supply. You will have to carefully check that there is no wiring error because all the components of the analog part are in place. An error could have serious consequences on the components.

No 'magic smoke' when reconnecting the transformer to the electronic board of this Drumulator. All regulated voltages are present. However, I have to resolve a small problem due to changing the transformer. This concerns displays and LEDs. Normally these elements are powered by the rectified but unregulated voltage supplied by the transformer. However, having not managed to get my hands on a transformer providing the same output voltages, I am now with not around ten volts but a little over fifteen volts. It's still a little too high.

So I placed a 10V regulator in the power line of these elements.

In order to finalize the operational check of the machine, now that all the voltages are present, and especially to test the sound generation and therefore the entire waveform sequencer part, as well as the analog part, I replaced all the components that I had removed during my first tests, as well as the temporary electrical connections.

And there, a pleasant surprise. I can hear the drum sounds coming out correctly through the line jack. A priori I don't encounter any problem except one of the other displays which lost a segment. It's really strange, this is the second display in this situation. I still have my last available display. I just have to replace it.

I will also try to place a small radiator under the new 10V regulator as well as on the regulators of the analog part. The voltages supplied by the transformer being slightly higher than the original ones, the linear regulators heat up a little more.

The repair of this machine is now almost complete!

After testing all the keys and functions of the machine, one of the sound trigger buttons remains that does not work. It's easy to repair. On the other hand, the linear potentiometer does not respond at all. I therefore cannot adjust the volume of the instruments, and those which have the volume at zero are therefore not available.

The cause of the problem was not difficult to find :

The problem is quite simple to determine. I had never seen this kind of problem in a potentiometer of this type, but I learned that the machine was 'violated' at a certain period of its life. This potentially explains this!

So I put this part of the slider back in place, adjusting it as best as possible. This operation is not that easy to carry out because when you apply the hot tip of the soldering iron to melt the plastic of the cursor, the metal blade finds itself 'swimming' in a rather viscous liquid, which makes positioning difficult. But :

After this operation and reassembly of the potentiometer in place in the machine, I was finally able to listen to all the basic sounds of the Drumulator. No distortion, the sounds are all very good.

I still have to resolve the RESET problem and the restoration will be complete. Afterwards, I will carry out some cosmetic operations and that will be the end of the return to life of this Drumulator.

Small update...

In fact, I just understood why the RESET circuit as it was implemented in the Drumulator is completely, hum... 'stupid'?

Until now, I 'just' applied a correction suggested by EMU to 'improve' the RESET. But I still had difficulty implementing this solution. The value of the capacitor must be tested each time. And it took so long that at the time I even completely recreated the RESET system.

I no longer have this system, I used all the prototypes I had made. So, as I stared blankly at the page concerning all the power supply in the electrical diagram of the machine, the 'thing' appeared to me in all its 'glory'!

I fixed the problem in a few minutes by placing a few components in the right places. Not only does it work, but it will continue to work, in fact, all the time now. Okay, I'll keep the solution to myself. It's like mushroom corners, we avoid revealing their location ;-)

well well well... All I have to do now is to place a 20CR32 battery holder for the RAM backup as well as a solution to evacuate the heat from the voltage regulator that I added.

Updated 06/19/2024

Obviously, this never happens as planned, especially on a very old machine that has had a fairly eventful life.

RESET of the machine is now actually carried out seemingly. On the other hand, saving RAM posed problems. In idea, the whole system of controlling the voltage, generating the RESET and protecting the saved RAM is well thought out, but it only takes one small detail that goes wrong and the whole system collapses.

And this is the case when the components start to age. And no, even by replacing the head capacitor in the 5V line, the system does not work again! But, again, I ended up finding the right way to ensure that the RAM saves correctly without corruption at startup. And no more 'Bad' message when restarting the machine.

OK, so the machine is finally fixed? Well no...!!!

Three sounds do not come out, they are the TOMs!

In fact, these are 'just' two ways that don't work. The TOMS HI and MID share the same sound generation channel.

And it's back to debugging. But this time, I'm moving directly towards the analog part, since it seems to me that the digital part of the sound generation works very well.

After some time searching, I actually found a problematic component. This is a quadruple TL084 which has a defective AOP. For the moment I have not investigated further, but I thought I had solved the problem of the two faulty channels, but in fact no, only the channel concerning the TOM LOW has become active again.

I still have to find the reason why the TOMs Hi & Mid are not working...

Updated 06/25/2024

This time it's good!

The machine outputs all the sounds well. It always starts correctly every time, and I haven't had a saved memory problem ('Bad' message at startup) since I fixed it.

So I had to replace two components. A quadruple AOP circuit of which two AOPs were dead out of the four. But that wasn't enough, one of the two analog output filters (SSM2044) was also dead.

The AOP, TL084 circuit is easy to replace. On the other hand, obviously, we no longer find SSM2044. Fortunately, there is a new version that works very well. It comes in CMS format, so this circuit must be placed on a DIP adapter.

Once these two components have been replaced, all sounds come out of the machine correctly. The new analog filter works as well as the original one.

The defective SSM2044:

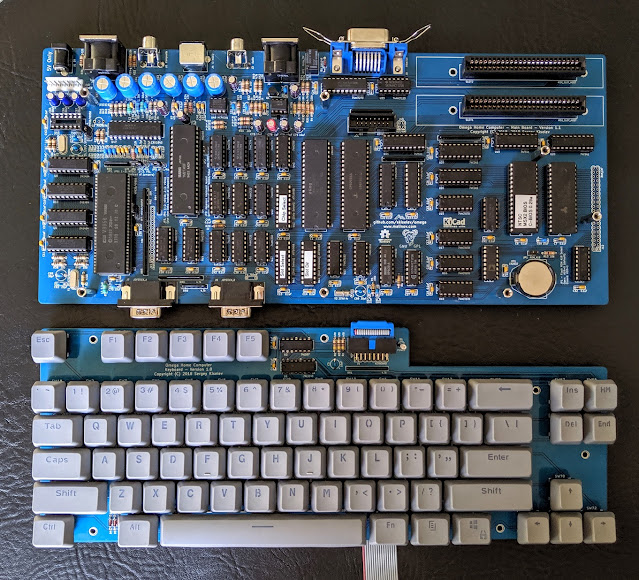

And the Drumulator board equipped with the two new integrated circuits:

All I have to do now is find a small metal blade to solder on the 10V regulator that I added, and also clean three switches which are really not pleasant to use because the contacts must be so dirty...

Thus ends the adventure of restoring this Drumulator. Nothing too complicated, but there are a whole series of small repairs, or adaptations to be made. All of these operations obviously take time. But the result is there!

And, icing on the cake, you can hear THIS Drumulator in this video:

In true 80s style : enjoy!

Updated 06/25/2024

Back to home :

Well surrounded by a TR505, a TR707 and two Mirages... 👍

And thank you to Philippe for his communicative passion!