THE DRUMULATOR

I continue the experiments of recreating the audio outputs of the Drumulator.

At this stage, I know that I am able to read all the Drumulator sounds correctly with the digital/analog converter used, once the data has been passed through the decompression table to the µLAW standard.

But, for the moment I reproduce the sound directly at the output of the audio converter. I now have to test on the one hand the individual volume adjustment part then the sample&hold outputs, in order to verify that the reproduction is going well on all the outputs.

It's a bit complicated because in order to minimize the need for board routing, I opted for serial interfaces for all the commands. Originally, the interfaces are of the parallel bus type with all that this implies of buffer circuits and bus locking.

And above all, I like to condense ;-)

Apart from the analog converter and the serial control circuit, I use the same components as those present in the Drumulator, just to preserve as much as possible the sound signature of this machine.

THE MSX OMEGA

This morning I received a package directly from Poland. Even if I blurred some information on my home address, I note that the French postal service still retains within it, some real clairvoyant eyes. I doubt that it happened correctly in the machine-reading system... Long live to the world of real people!

And what's beautiful inside this 'survivor' package?

Everything you need to build a great case for the OMEGA board. All I have to do is find the few screws needed to fix the board to the bottom of the case. Interesting thing: I find that my USB to OMEGA keyboard conversion interface fits perfectly inside the box without any problem. I should even have room to attach a USB connector to the front panel. From the cutout informations, I thought my interface wasn't going to fit inside. In fact, it does it very well and I'm very satisfied!

The difference in this version is that there is no cutout for the Omega keyboard as originally planned since I am replacing it with a USB keyboard. I indeed thought that it was not going to be practical to type on the keyboard placed in the high position. I was right. It will be much more practical with a 'normal' keyboard.

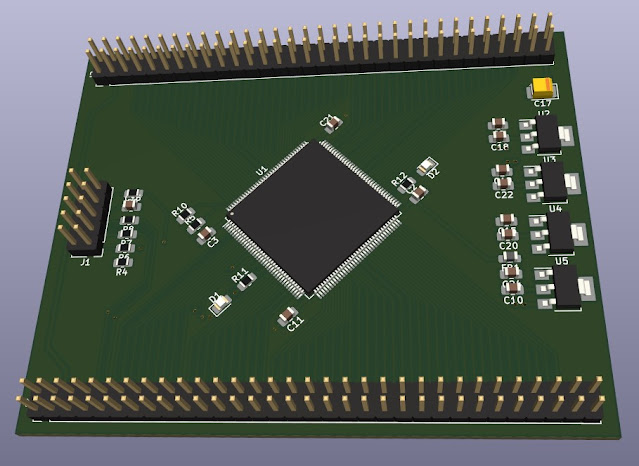

So, I'm thinking about building a cartridge to easily develop software for the Omega. I know that there are many solutions, including the one that consists of using a ROM cartridge of the MSXROM512 type from Raphnet, on which we place an EPROM emulator to easily upload the code, once validated in the emulator,

but I am going to try to develop a cartridge that can be loaded natively via a USB port and also equipped with a serial port.

Because in fact, I'm not very 'games' with computers but rather communication. I would love to connect this Omega somehow to the NET.

Many thanks to Krzysztof Odachowski for the realization of this enclosure...