In the previous post on this subject, I had stopped at the fact that I had discovered that the wiring of the EPROM to the processor did not respect the conventions. I therefore confirm this fact, and am even able to say that all EMU1 motherboards have this characteristic which can be defined as a relatively simple coding of the EPROM whose purpose is, I think, to make the disassembly of the program difficult.

To come to this conclusion, I read the original EPROM from my EMU1 motherboard. To do this, I placed the EPROM on a circuit socket from which I cut off the +12V and -5V power supply pins. Because the MiniPro is not able to provide these power supplies on these pins. So I was able to connect these two EPROM pins directly to an external laboratory power supply.

|

MiniPro

|

|

| Socket adaptor |

In fact, in order to be able to test the operation of this motherboard, I had originally removed the +12V and -5V power supply from this EPROM. The goal was to be able to eventually test the operation of the board with another version of the boot program. This also allowed me to check the behavior with the logic analyzer and draw my conclusions as to how this EPROM is connected to the processor.

Note that to read the EPROM on the MiniPro, I selected a 2716 type EPROM, the smallest available on the software, knowing that I would therefore have twice the same KB read since the original EPROM is a 2708 and the additional address bit of a 2716 is not connected to the 2708.

So, now that I am sure that the motherboard of this EMU1 works, since it is able to execute my 'NOP' loop, I need to continue on the right basis, that is to say, program a 2732 that I have with the original EPROM program and insert this 2732 in place of the original 2708.

On the other hand, EMU strongly advises to always use the original EPROM to perform tests. So...

I don't know why this exists, but I strongly suspect it has to do with some hardware feature. Since the boot program just reads the first track of the floppy anyway and then runs this firmware to load the entire floppy, I suspect it has to do with just some basic motherboard functions. I don't know more than that at this point. Potentially setting a timer?

In fact, I compared the contents of the EPROM of my EMU1 board with other contents of different versions found on the Internet, I noted different codes at the addresses:

0x208

0x228

0x237

At least, the code in 0x237 is different on all the contents. The 4-voices version also has a difference in 0x208, and the Wildcard version, has the 3 differences.

Be careful, these codes at these addresses do not mean anything. They correspond to a specific code at a specific location, but after reorganization of the code according to the wiring of the EPROM to the processor.

The versions tested were the following:

600X.PROM(c)82_820816_#008D.BIN (The one on my board)

820816-00B8.bin

820816-0081.bin

820816-0165.bin

820816-0181.bin

E14Voice2708.BIN

Emu_wildcard.bin

At this point, and after inserting an EPROM containing the original boot program of my EMU board, nothing happens at the floppy drive. On the EMU1 board, the voice DMA controllers are not inserted. Only the principal DMA controller is inserted on its socket. In this configuration, I know that the boot program starts and runs. Despite the fact that this situation is not optimal for the minimal operation of the motherboard, something should still happen at the floppy drive, namely at least the rotation of the disk. However, nothing happens.

And this is when I change the first component that I think is defective on my board, namely the SIO. In fact, it is this SIO that generates the floppy drive selection signal, which has the effect of starting the floppy disk rotation motor.

After this intervention, indeed, the rotation motor starts correctly. This is a good start, but nothing else happens. However, before anything else, in any procedure for reading a floppy disk, the controller must ensure that the reading head has returned to its initial position. Three signals are then important, the movement direction signal, the control signal for the stepper motor for positioning the reading head, and the track 0 position return signal. And these signals are managed not by the board's SIO, but by the PIO.

So I also replace this PIO.

After replacing these two components, indeed, by powering the motherboard back on, randomly, the floppy drive not only starts, but its head moves slightly to test the positioning of track 0. So I am also on the right track!

Of course, at this point I can't avoid to ask myself a few questions. How come the two interface components with the floppy drive are defective? On my workbench, the system is in the same configuration as in the EMU1 box. Is there a power supply problem in the EMU1? Because on my workbench, everything is powered by a laboratory power supply. Before reassembling this EMU1, I had obviously checked the proper functioning of the power supply that I had recapped. Strange all that!!!

Well, now I have a system that seems to boot properly from time to time. That is, it boots the floppy drive and sets the read head to track 0. But nothing more. The randomness doesn't surprise me either. The current configuration of the DMA components is not good at all. Besides, I'm now dealing with these DMAs.

It may not be very obvious at first glance, but the DMA system takes care of all data transfers with the floppy disk drive, in addition to managing the sound by sending the samples to the digital/analog conversion boards.

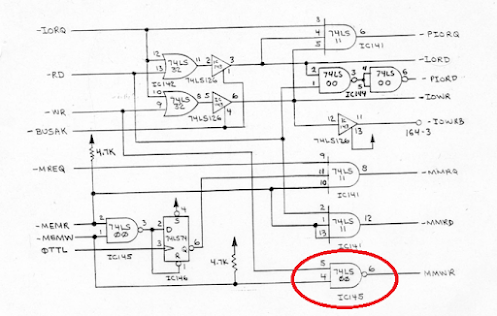

And, a quick reading of the schematic indicates that it is the first channel of the first DMA controller for reading samples that is used. Quite simply by assigning its signals, not to the conversion board, but to the floppy drive when accessing this drive. In order to make the board undisturbed by the absence of the conversion boards, I therefore position certain signals to ground, as indicated on the schematic provided by EMU. In fact, I only keep the first DMA controller and I remove any random character of a DMA trigger by the conversion boards.

In fact, I only leave the DMA controller #1 (I'm not talking about the head one which must be in place anyway). This is materialized by grounding some signals on the EMU1 motherboard.

Well, it's not meant to stay like this in the long term ;-)

And now I can power up this great EMU1 board again. Good 'surprise', the boot sequence now runs correctly and in the same way after each RESET of the board. The disk rotation motor starts, the reading head is positioned at track zero, even when I previously moved it by hand.

But for now, the situation seems frozen in this state. According to the EMU documentation, track 0 should be read then saved in RAM then executed to completely load the floppy disk. I performed my tests with a floppy disk containing the system but nothing works. I now need to check with the oscilloscope that the data from the floppy disk arrives correctly at the SIO of the EMU1 motherboard.

So I also have to deal with the interrupt management chain because it may 'block' at that level. I imagine that the SIO generates some of them, in any case it is wired for that and even has the maximum priority. A priori the interrupt chain stops at the PIO, the DMA controllers do not manage interrupts in this system.

This is the next step. It's laborious, but it's progressing!